Flexographic Printing for Custom Paper Shoppers and Plastic Bags

Flexographic printing is a direct printing process that uses water-based inks, widely employed for automatic paper and plastic bags, counter paper and adhesive labels. The ink is transferred directly onto the surface of the material through a rotary printing system, ensuring colour uniformity and fast production times even on large print runs.

Due to the nature of water-based inks, tones printed on darker backgrounds may appear more intense, except for metallic inks such as gold and silver, which maintain uniform coverage and a refined finish.

Attention: On paper shoppers (except for models in the CUSTOM SERIES), the print area is limited to the two main sides and may be affected by the presence of handles and side gussets. In two-colour artwork, it is not possible to print two shades directly in contact. We strongly recommend consulting our technical team before placing an order to confirm feasibility. This limitation does not apply to CUSTOM SERIES models.

Main Features of Flexographic Printing

- Direct printing on paper or plastic using eco-friendly, water-based inks.

- Allows one- or two-colour printing on both sides of the surface.

- Suitable for porous and non-porous materials (kraft paper, PE or PP plastic, counter paper).

- Excellent colour coverage with quick drying times.

- Perfect for medium to large production runs with reduced setup costs.

Ideal for Personalising

- Paper shoppers and kraft bags – natural or white, with flat or twisted handles.

- Plastic bags – neutral or coloured, suitable for fairs, shops and promotional events.

- Counter paper and food wrapping paper – perfect for bakeries, patisseries and gourmet stores.

- Paper bags – ideal for packaging or product communication.

Note on Colour and Printing Backgrounds

In flexographic printing, only the ink colour is considered, regardless of the substrate colour. For best results, the printed colour should be darker than the background. For example, printing yellow on a blue base is not recommended, as it reduces legibility. For dark materials (black, blue, burgundy, etc.), metallic inks such as gold or silver are advised to ensure higher opacity and crisp definition.

Available Pantone colours: for print runs under 3,000–5,000 units, the main Pantone U colours available for flexographic printing are: Fuchsia Rhodamine Red U, Pink 1895C, Orange 021U, Red 186U, Medium Green Green U, Dark Green 342U, Apple Green 382U, Purple 266U, Light Blue 299U, Blue 072U / 295U, Brown 477U / 7517U, Yellow Hexachrome Yellow U, Grey 430U, Bordeaux 208U, Tiffany Green 319U, Teal 321U, Black Process Black U, Gold 871U, Silver 877U, Bronze 876U.

Benefits of Flexographic Printing

- High productivity and consistent results across large quantities.

- Excellent logo and text clarity, even with metallic colours.

- Competitive printing costs and short turnaround times.

- Environmentally friendly thanks to water-based inks.

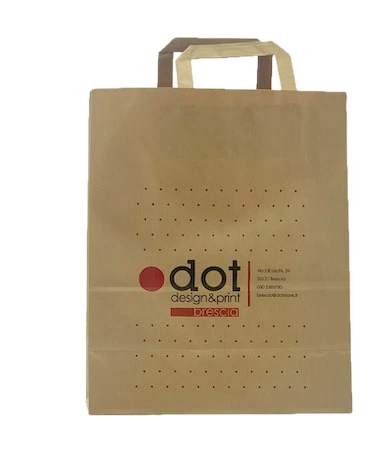

Examples of Flexographic Printing

Here are some real examples of flexographic printing applied on paper and plastic surfaces:

All images show real flexographic prints on paper and plastic, optimised for sharp, durable and consistent visual results.

Return to the overview of printing techniques to compare all printing methods and applications available on Shop for Shop.